|

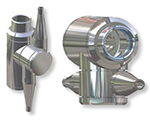

Rotary Nozzle

|

|

Type LT & LT-FT Tank Cleaning Machines |

Brochure - Type: LT & LT-FT |

The Butterworth Type LT automated tank cleaning machine provides 360° impact indexed coverage for the cleaning of the inside of tanks and process vessels. |

Industries

The Butterworth LT is a highly versatile machine and is applicable in most all types of tanks for process, storage, and transportation. Tank capacities range from 500-150,000 gallons (2-570 M3) for one machine per tank and larger tanks where multiple machines are installed. |

| |

User Benefits: |

Operational

The Butterworth LT machine creates a pattern matrix similar to a ball of twine (see cleaning pattern simulation in the lower right hand corner of this page). A complete pattern is established when 65 axial revolutions of the body have been completed. During the process of this pattern build out, 4 cycles are established with each cycle increasing the density of the pattern matrix.

|

- Elimination of confined space entry

- High jet-stream impact

- Reduced cleaning times

- Reduced effluent generation

- Reduced energy costs

- Improved capital equipment utilization

|

|

| |

Return to Last Page |

|

|

|

Type BC (FT Only) Tank Cleaning Machine |

Brochure - Type: BC (FT Only) |

The Butterworth Type BC automated tank cleaning machine provides 360° impact indexed coverage for the cleaning of the inside of tanks and process vessels. |

Industries

The Butterworth Type BC is a highly versatile machine

and is applicable in most all types of tanks for process,

storage, and transportation. Tank capacities range from

500-45,000 gallons (1.8-170 M3) |

| |

User Benefits: |

Operational

The Butterworth Type BC machine creates a pattern matrix similar to a ball of twine (see cleaning pattern simulation in the lower right hand corner of this page). A complete pattern is established when 65 axial revolutions of the body have been completed. During the process of this pattern build out, 8 cycles (for a 4nozzle hub) and/or 4 cycles (for a 2 nozzle hub) are established with each cycle increasing the density of the pattern matrix.

|

- Hygienic design

- High jet-stream impact

- Reduced cleaning times

- Reduced effluent generation

- Reduced energy costs

- 100% self-rinsing (for specific models)

- Improved capital equipment utilization

|

|

| |

Return to Last Page |

|

|

|

Type LTQ (FT Only) Tank Cleaning Machine |

Brochure - Type: LTQ (FT Only) |

The Butterworth Type LTQ automated tank cleaning machine provides 360° impact indexed coverage for the cleaning of the inside of tanks and process vessels. |

| The Butterworth Type LTQ is a highly versatile machine and is applicable in most all types of tanks for process, storage, and transportation. Tank capacities range from 13,000 to 130,000 US gallons (50-500 M3). |

| |

User Benefits: |

Operational

The Butterworth Type LTQ machine creates a pattern matrix similar to a ball of twine (see cleaning pattern simulation in the lower right hand corner of this page). A complete pattern is established when 65 axial revolutions of the body have been completed. During the process of this pattern build out, 8 cycles are established with each cycle increasing the density of the pattern matrix.

|

- Hygienic design

- High jet-stream impact

- Reduced cleaning times

- Reduced effluent generation

- Reduced energy costs

- 100% self-rinsing (for specific models)

- Improved capital equipment utilization

|

|

| |

Return to Last Page |

|

|

|

Type MICRO100A Tank Cleaning Machine |

Brochure - Type: MICRO100A |

The Butterworth Type MICRO100A automated tank cleaning machine provides 360° impact indexed coverage for the cleaning of the inside of tanks and process vessels. |

Industries

The Butterworth Type MICRO100A is a highly versatile machine and is applicable in most all types of tanks for process, storage, and transportation. It can be used as a portable unit or permanently mounted. |

Operational

The Butterworth Type MICRO100A machine creates a pattern matrix similar to a ball of twine. A complete pattern is established when 36 axial revolutions of the body have been completed. During the process of this pattern build out, 4 cycles are established with each cycle increasing the density of the pattern matrix. The variable speed motor allows for flexible cycle times.

|

|

| |

Return to Last Page |

|

|

|

Type CAT Tank Cleaning Machine |

Brochure - Type: CAT |

The Butterworth Type CAT automated tank cleaning machines is a fully programmable, single nozzle machine designed with pitch and speed control for cleaning the inside of tanks and process vessels. |

| The Butterworth Type CAT is a versatile, maintenance friendly machine that can be used in all types of tanks for process, storage and transportation. The programmable pattern feature allows for rapid cleaning cycles at reduced cleaning fluid consumption. |

| Operational |

User Benefits: |

The Butterworth Type CAT features an externally mounted gearbox and turbine. This allows for maintenance on the machine, without pulling the main body from the vessel. Through the programmable gearbox, vertical pitch is controlled through three pitch settings of approximately 2, 4 and 9 degrees. This combined with two speed settings, provides a total of six basic cleaning patterns..

|

- Elimination of Confined Space Entry

- High Jet-Stream Impingement

- Reduced Cleaning Times

- Reduced Effluent Generation

- Reduced Energy Costs

- Reduced Maintenance and Installation costs

|

|

| |

Return to Last Page |

| |

|

|

Spray Ball

|

|

Type UBC Rotating Spray Head |

Brochure - Type: UBC |

The Butterworth Type UBC rotating spray head projects sheets of water on a variety of spray patterns, using low volumes of water with considerably higher fluid impact values when compared to conventional static spray balls. |

In Application

The Type UBC device can be used in hygienic and non-hygienic applications. The device is 100% self-rinsing. A variety of connection types are available and typically are installed permanently in a given tank or vessel. The Type UBC device can also be used on a portable basis when desired. |

Typical Industries Served: |

|

- Soup kettles

- Yeast propagation tanks

- Batch processing vessels

- Fluid bed dryers

- Ink and paint mixing vats

- Brew kettles

- Storage tanks

- Spray dryers

- Commercial ovens

|

Operational

The flow of fluid through the Type UBC device will cause the projections of fluid through the fluid slots of the unit. This flow of fluid is at a slight angle to the radius of the ball and causes a transitional reaction. This reaction sets the ball in rotation. Rotation speed of the ball is relative to the fluid pressure exerted at the inlet of the device. |

|

| |

Return to Last Page |

|

|

|

Type UAA Static Spray Balls |

Brochure - Type: UAA |

Butterworth Static Spray Balls are simple, fast, and efficient devices for rinsing the inside of tanks in a variety of industries. All units are self cleaning and available in a variety of spray patterns and surface finishes. |

Industries

Static Spray Balls can be used in hygenic and non-hygenic applications. |

Typical Industries Served: |

|

- Food

- Brewing

- Dairy

- Pharmaceutical

- Cosmetic

- Biotech

- Chemical

- Beverage

|

Operational

Static Spray Balls project a predetermined spray pattern based on the drilling arrangement of the holes within the ball. Typically, rinsing is accomplished by creating the desired coverage and cascading effect required for the relative cleaning task. |

|

| |

Return to Last Page |

|

|

|

Type UBA Single-Axis Rotating Spray Ball |

Brochure - Type: UBA Single-Axis |

The Butterworth UBA Rotating Spray Ball is designed to distribute cleaning media in tanks ranging in size up to 22 feet (6.7 meters). The UBA is a single axis rotary spray ball that projects a predetermined spray pattern within a given tank geometry. The rotation of the spray ball is controlled mechanically to avoid over rotation, which would result in reduction of spray radius and impact values of the media. |

Applications Benefits |

|

- Increased cleaning radius over non-controllable rotating spray balls

- Lower cost compared to 3D machines

- Minimal maintenance requirements

|

|

|

| |

Return to Last Page |

|

|

|

Type UBD Rotating Spray Head |

Brochure - Type UBD |

The Butterworth UBD rotating spray head offers 360° coverage for the cleaning of the inside of small tanks, process vessels, pipes, and other small containers. |

Industries

The Butterworth UBD is designed to rinse vessels and tanks. As standard, made completely of high quality 316L stainless steel with a high polished finish. Typical industries are Food, Beverage, Fine Chemicals, Pharmaceutical, Paints and Coatings…as well as other applications where the stated output parameters are applicable. |

Operational

The Butterworth UBD rotary tank washing nozzles operate by liquid being injected under pressure through an annular series of holes and striking a specially designed disk-like free-spinning structure whose curvature is such that the impinging liquid causes the disk to rotate, flinging off drops in the process. The bearing surfaces are Teflon, which promotes long-term reliability.

The series of nozzles produces smaller drops and develops less impact than some other types of single-axis rotary nozzles (i.e. UBC). However, there are distinct advantages in applications where the cleaning does not involve hard-to-remove residues.

The washing cycle is generally short compared to other designs so that liquid usage is minimized. Moreover, the orifices through which the liquid flows are quite large, minimizing clogging.

|

|

| |

Return to Last Page |

|

|

|

Type UBF Rotating Spray Head |

Brochure - Type: UBF |

The Butterworth UBF rotating spray head offers 270° coverage for

the cleaning of the inside of small tanks, process vessels, pipes,

and other small containers. |

Industries

The Butterworth UBF has been designed to fit through an opening

as small as 1.00" in diameter. As standard, made completely

of high quality 316L stainless steel with a high polished finish.

Typical uses are small comtainers used within the beverage

industry; small bore pipes, and as augmentation to larger CIP

installations. |

| |

User Benefits |

Operational

The Butterworth UBF is a Rotating Spray Head (RSH) and

completes a full pattern in one rotation of the head. The higher the

inlet pressure, the faster the rotation of he head itself. The amount

of run time and pressure will vary… depending on the cleaning

requirement |

- Reduced Cleaning Times

- Reduced Effluent Generation

- Reduced Energy Costs

|

|

| |

Return to Last Page |

| |

|

|

|

|

|